• Precision Reliability Output

Steam Turbine & Spares

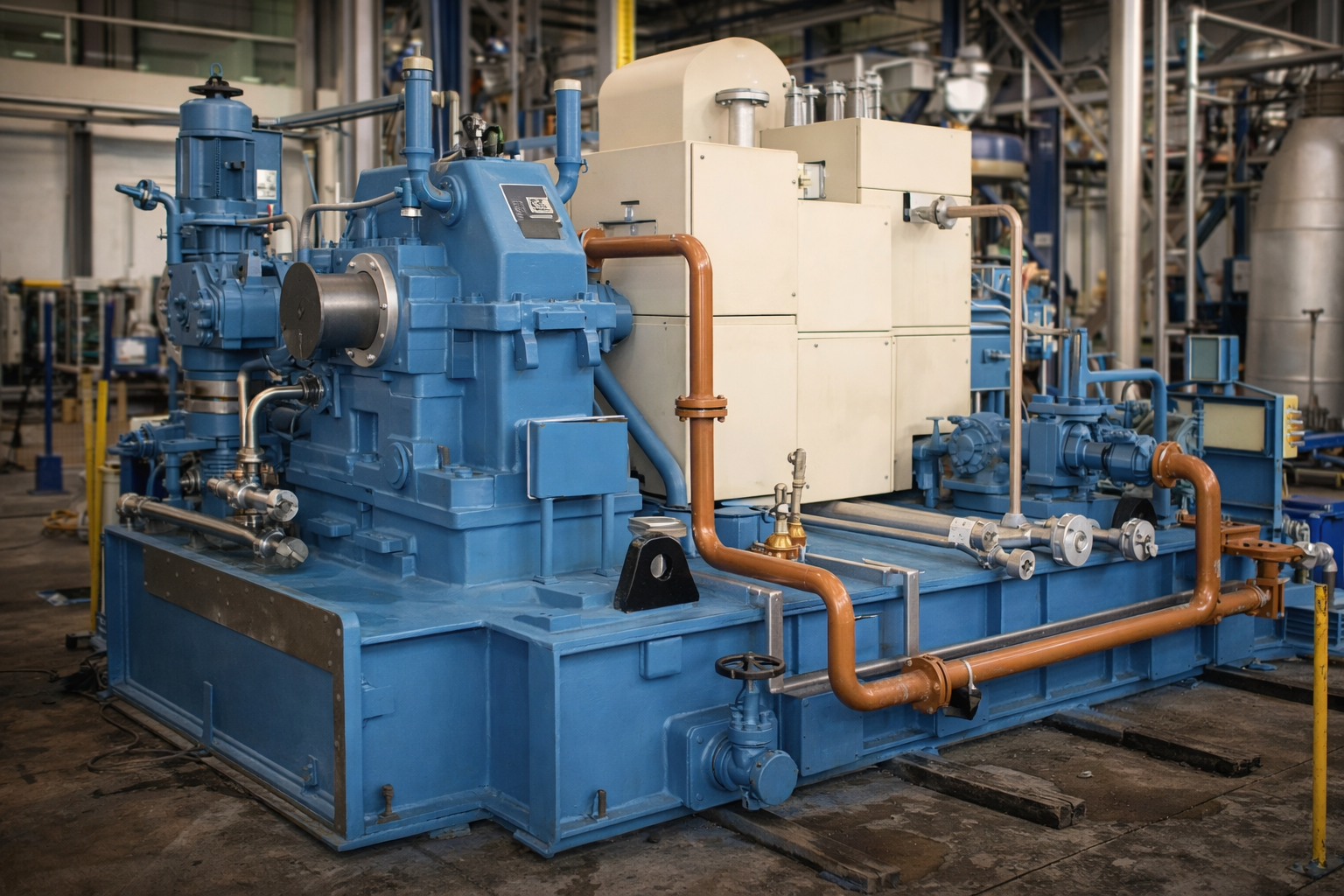

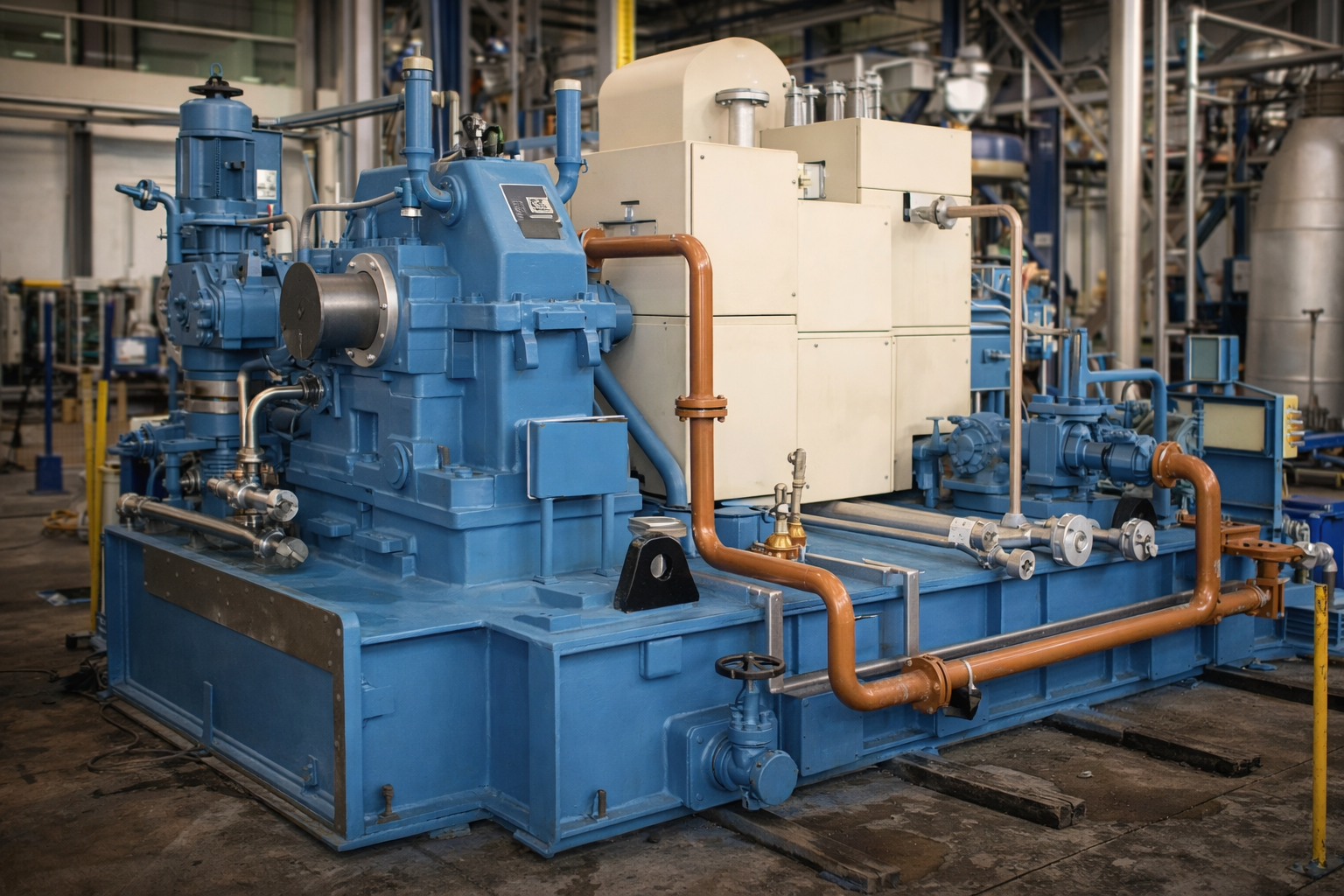

We provide complete steam turbine solutions, including manufacturing, supply, spares, servicing, overhauling, and reverse engineering for industrial steam turbines. Our solutions are designed to deliver high efficiency, reliable power generation, and long operational life across diverse industrial applications.

We deal in Micro Steam Turbines, Saturated Steam Turbines, Back Pressure Multi-Stage Steam Turbines, Condensing Steam Turbines, and a complete range of steam turbine spares and critical components.

Our Steam Turbine Range

Micro Steam Turbine

Saturated Steam Turbine

Back Pressure Multi-Stage Steam Turbine

Condensing Steam Turbine

Reverse Engineering

Spares Parts

Micro Steam Turbine

Compact turbines used for small-scale power generation in process industries and for demonstration/proof of concept purposes.

Key Features:

- ✔Compact and space-saving design

- ✔Easy installation and maintenance

- ✔Suitable for continuous operation

Applications:

- •Waste heat recovery systems

- •Demonstration in Engineering Colleges/Research Institutes

- •Small industrial power generation

- •Process industries with low pressure steam flow

- •Proof of concept for big Projects

Saturated Steam Turbine

Saturated steam turbines operate using saturated steam conditions, making them ideal for industries with stable steam parameters.

Key Features:

- ✔Simple and robust construction

- ✔Reliable performance under constant steam conditions

- ✔Lower operational complexity

- ✔Cost-effective solution

- ✔Continuous Working

- ✔Simplified Grid Synchronization

Applications:

- •Jaggery industries

- •Paper industries

- •Chemical processing plants

- •Rice Mills

- •Textile Mills

Back Pressure Multi-Stage Steam Turbine

Back pressure turbines generate power while exhausting steam at usable pressure for process heating, making them ideal for cogeneration systems.

Key Features:

- ✔Multi-stage design for better energy extraction

- ✔Efficient power and heat utilization

- ✔Controlled exhaust steam pressure

- ✔High operational reliability

Applications:

- •Cogeneration plants

- •Sugar and paper mills

- •Process industries requiring steam and power simultaneously

Condensing Steam Turbine

Condensing steam turbines are designed to extract maximum energy from steam by condensing exhaust steam under vacuum conditions.

Key Features:

- ✔High power output

- ✔Maximum thermal efficiency

- ✔Suitable for large steam flow

- ✔Optimized for continuous power generation

Applications:

- •Power plants

- •Cement industries

- •Large manufacturing units

- •Captive power generation systems

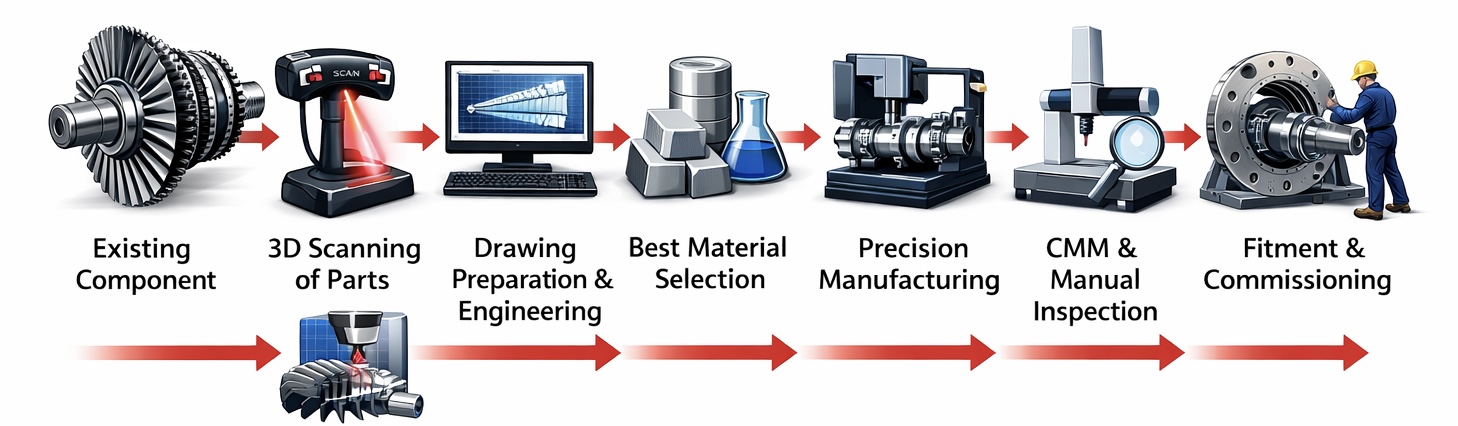

Reverse Engineering

Engineering Accuracy. Recreated.

NS Terbo delivers high-precision reverse engineering solutions for steam turbines and critical rotating equipment where OEM data, drawings, or spares are unavailable. By integrating advanced dimensional measurement, detailed engineering analysis, and controlled manufacturing, we accurately recreate turbine components that meet functional, dimensional, and material integrity requirements.

Our Technical Process

- ✔Detailed inspection & high-accuracy 3D measurement

- ✔CAD modelling & engineering drawing preparation

- ✔Material grade evaluation & selection

- ✔Precision machining & controlled manufacturing

- ✔CMM & manual dimensional verification

- ✔Assembly, fitment & site support (if required)

Components We Reverse Engineer

- ✔Turbine blades, rotors, shafts & couplings

- ✔Casings, diaphragms, nozzles & seals

- ✔Obsolete, discontinued, or imported spares

- ✔Worn, damaged, or performance-degraded parts

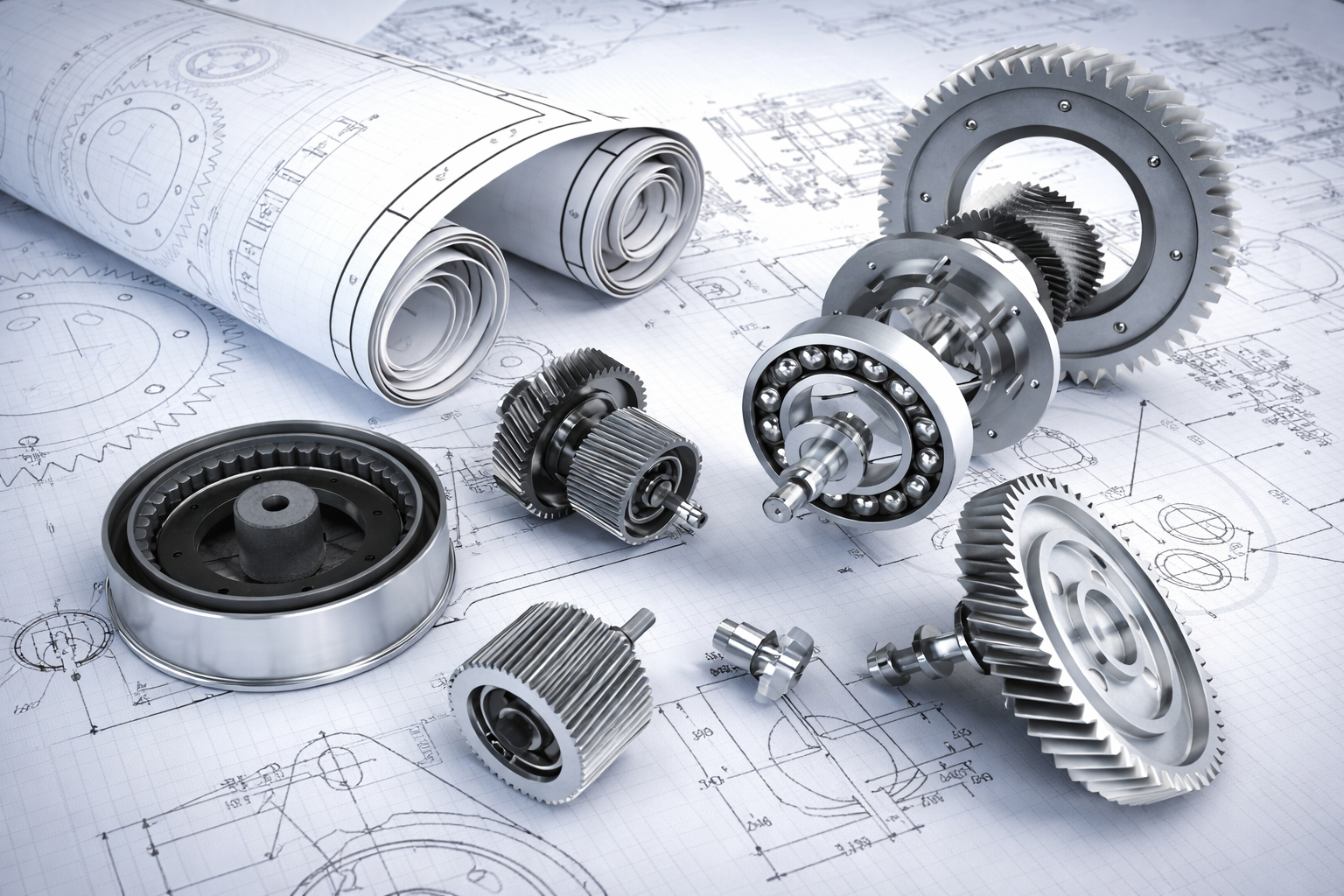

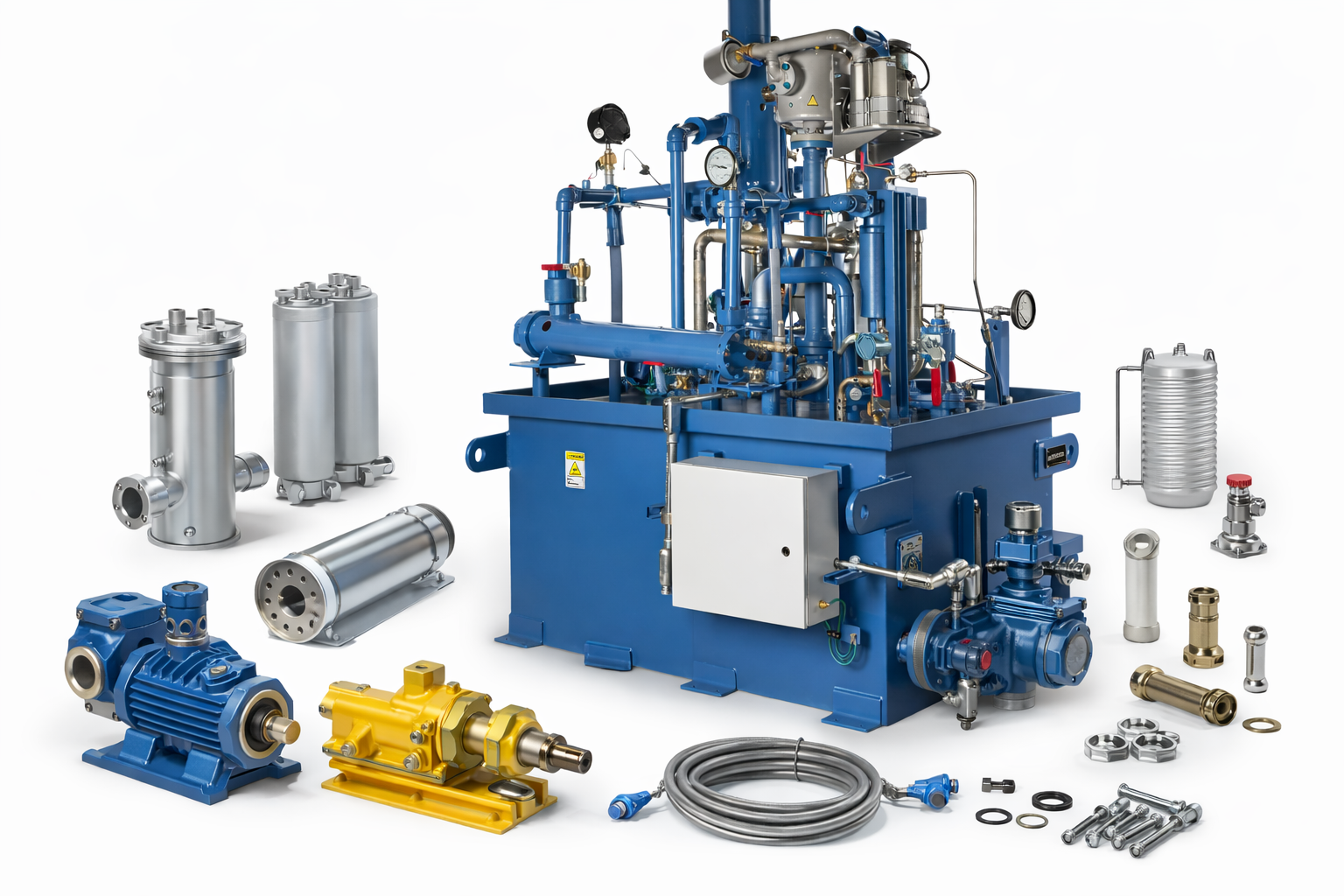

Steam Turbine Spares & Sub-Parts

Rotor & Blades

Bearings

Gland Steam Sealing System

Control Valve Components

Lube Oil System Components

Couplings

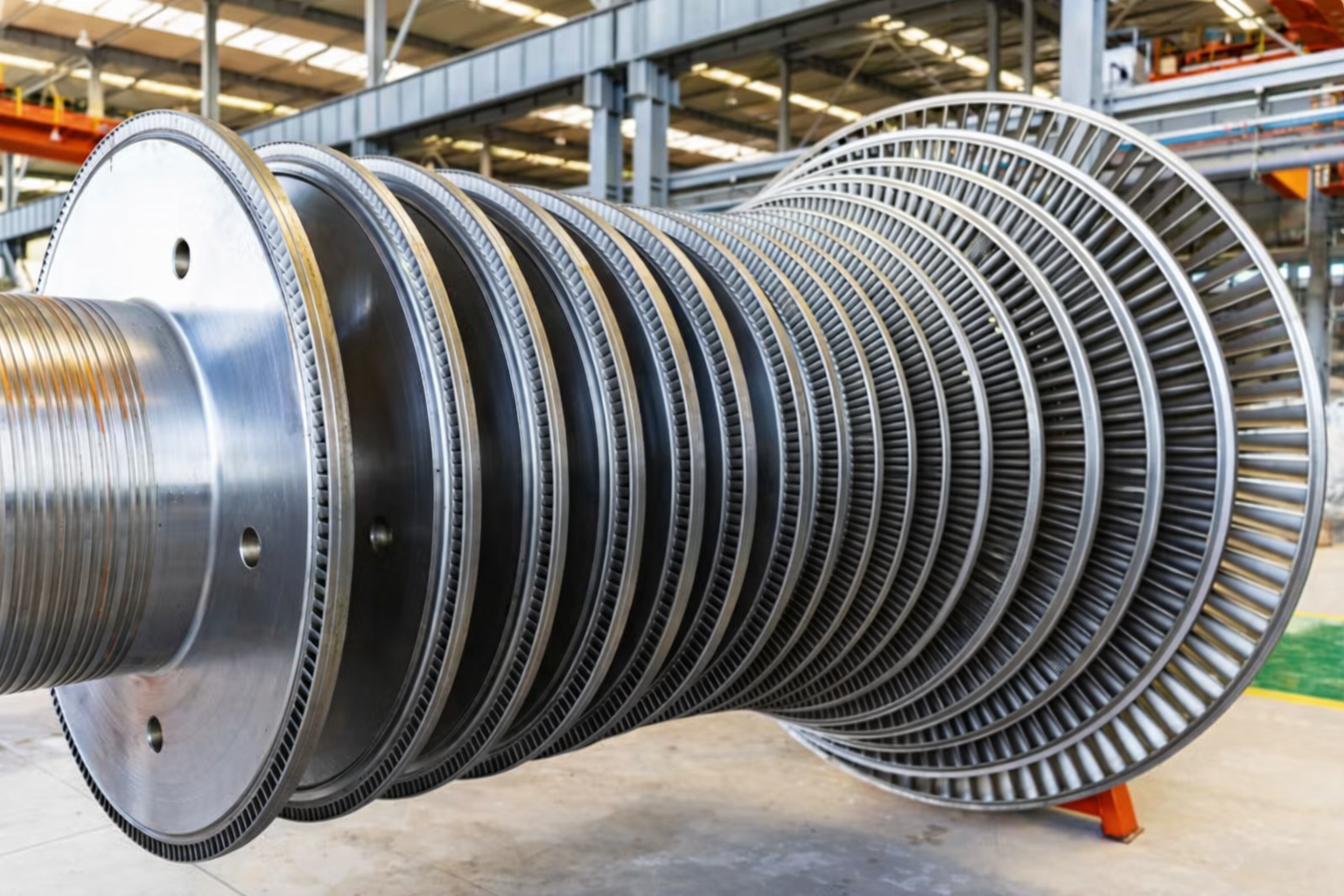

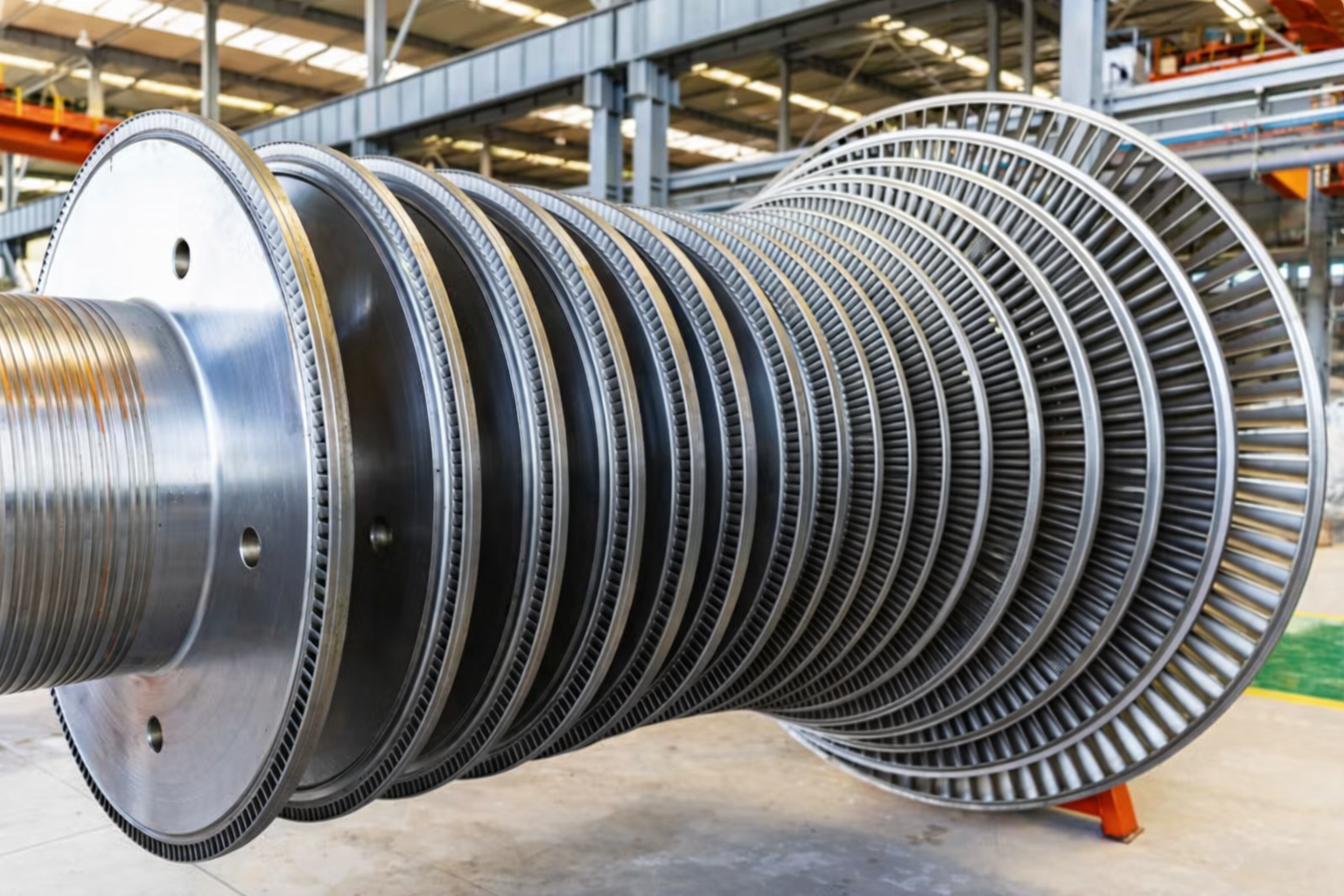

Rotor & Blades

The rotor and blades convert thermal energy of steam into mechanical rotational energy.

Components/Features:

- ✔Precision-manufactured blades

- ✔Dynamic balancing up to Grade 2.5 G

- ✔Re-blading and rerating as per requirement

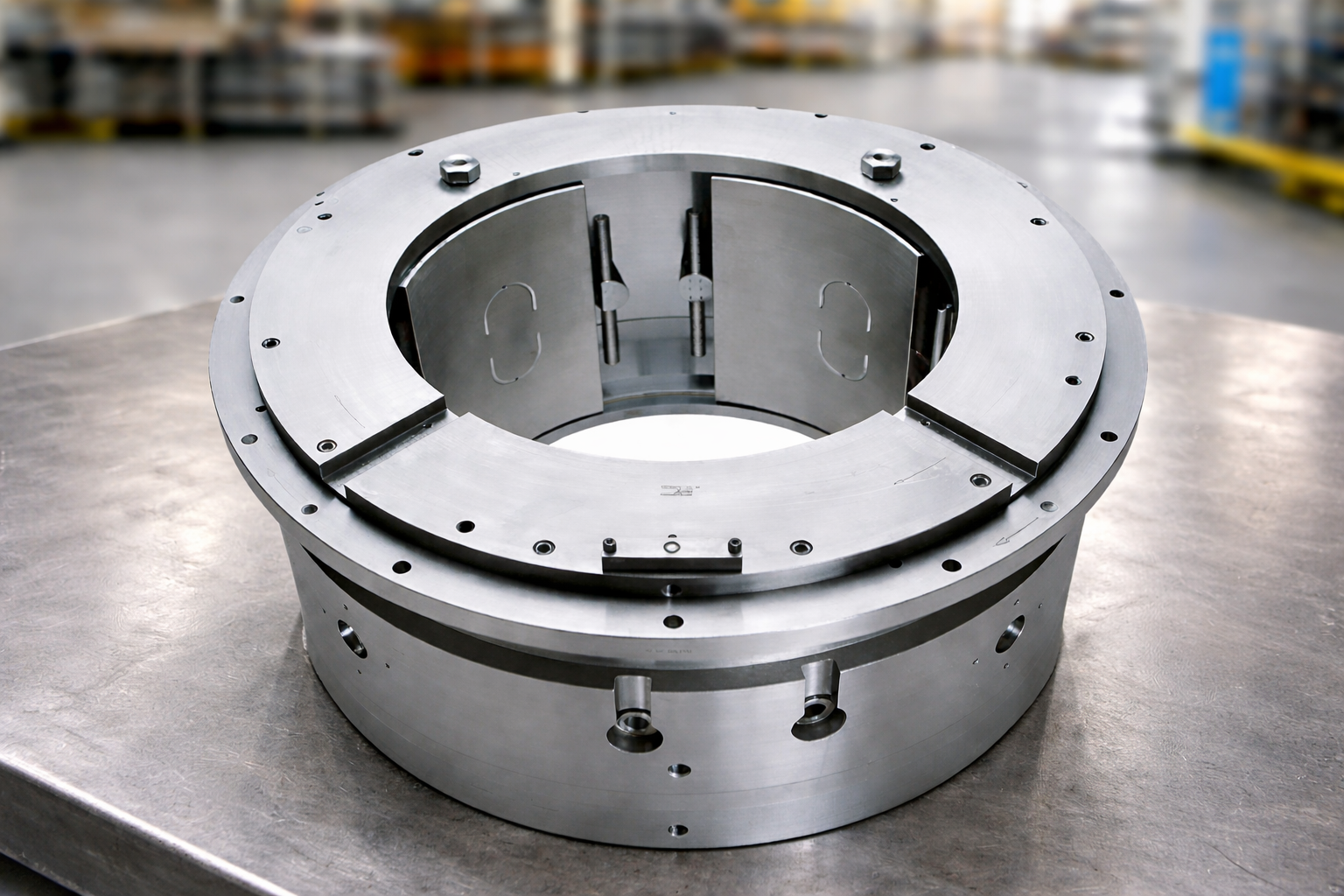

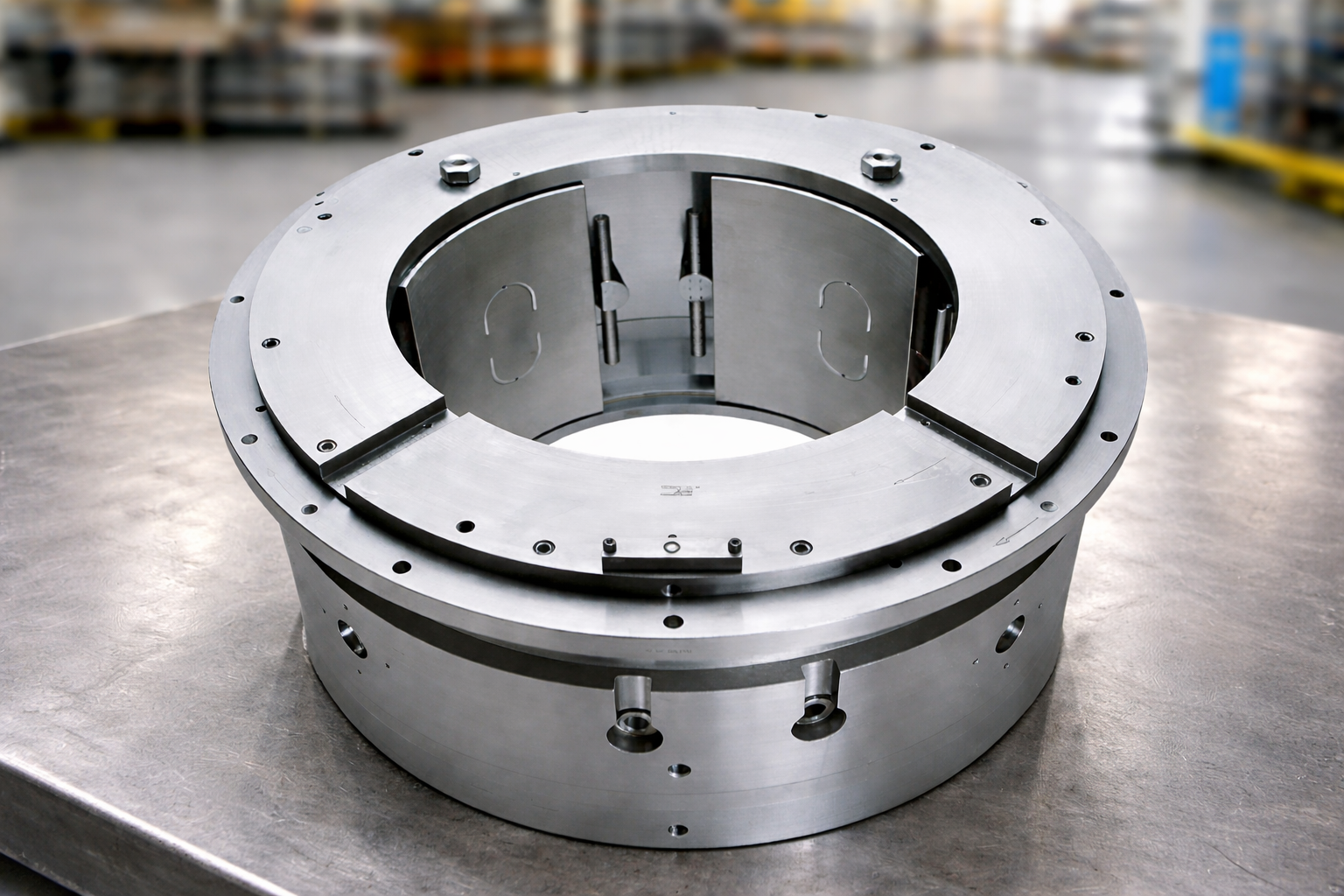

Bearings

High-quality bearings for smooth turbine operation and extended equipment life.

Components/Features:

- ✔Journal Bearings

- ✔Tilting Pad Journal Bearings

- ✔Tilting Pad Thrust Bearings

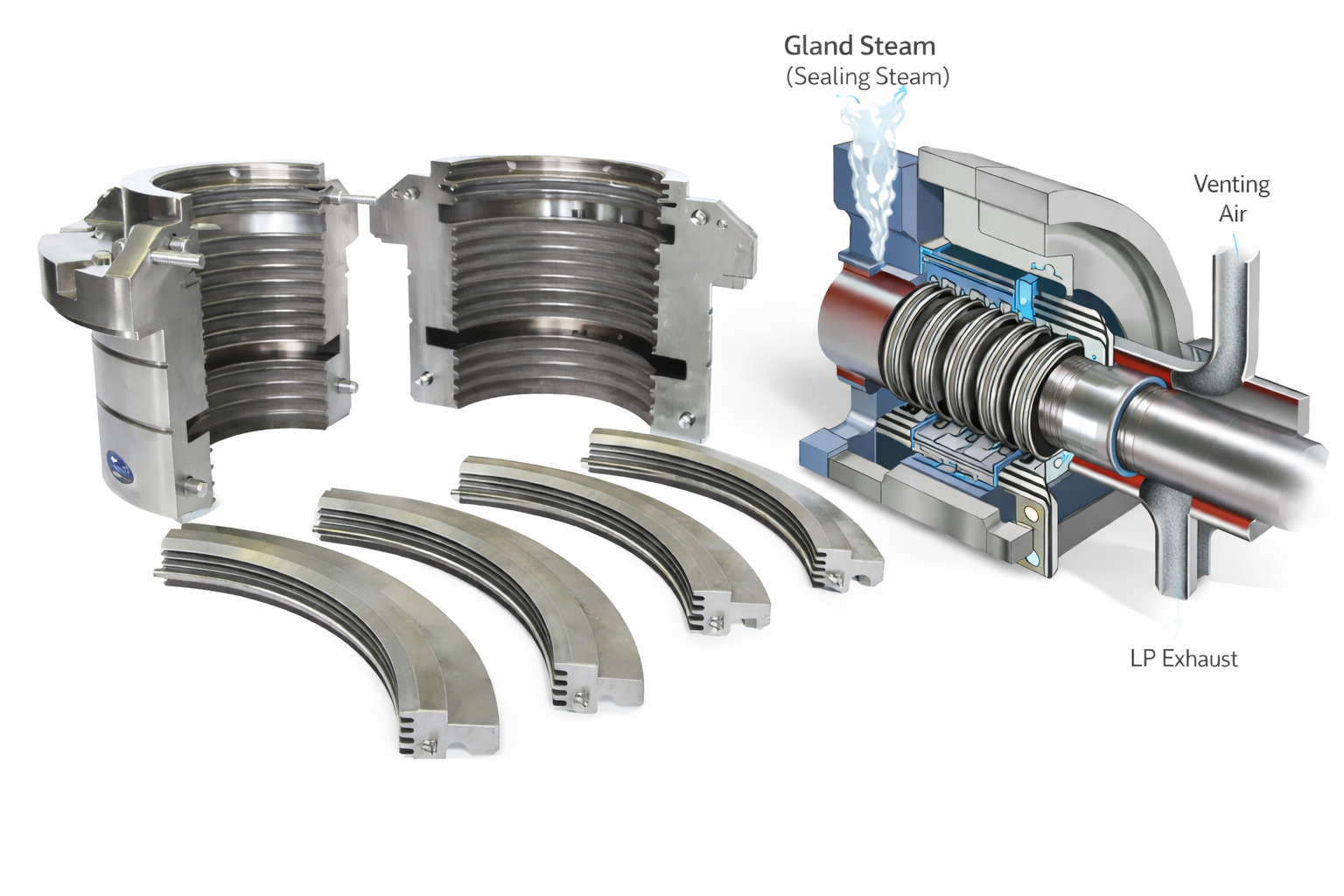

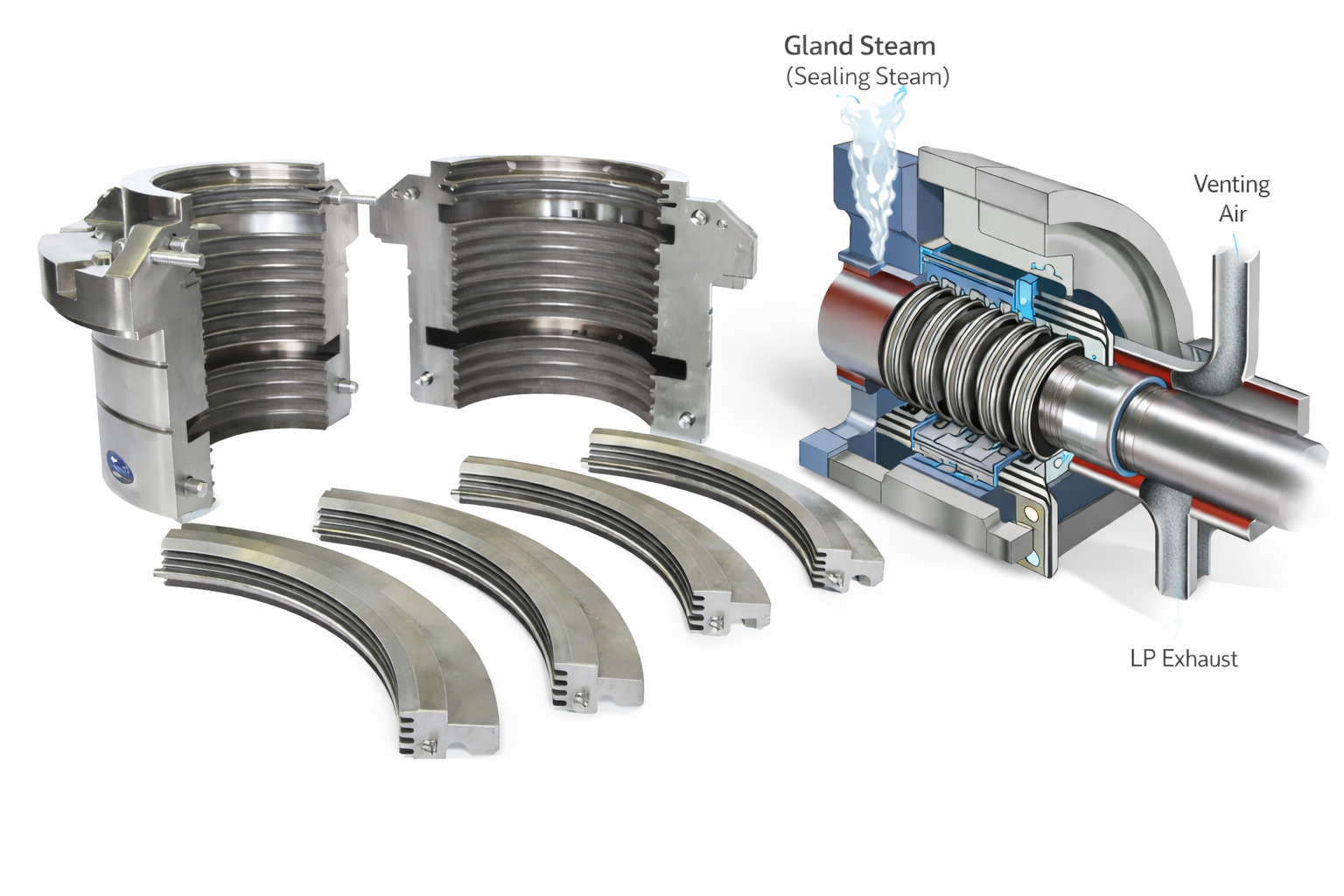

Gland Steam Sealing System

Critical sealing components to prevent steam leakage and ensure optimal performance.

Components/Features:

- ✔Carbon rings

- ✔Stainless steel sealing fins

- ✔Labyrinth rings

Control Valve Components

Precision-engineered control valve components for accurate steam flow regulation.

Components/Features:

- ✔Control valve spindles

- ✔Control valve bushes

- ✔Gland packing rings

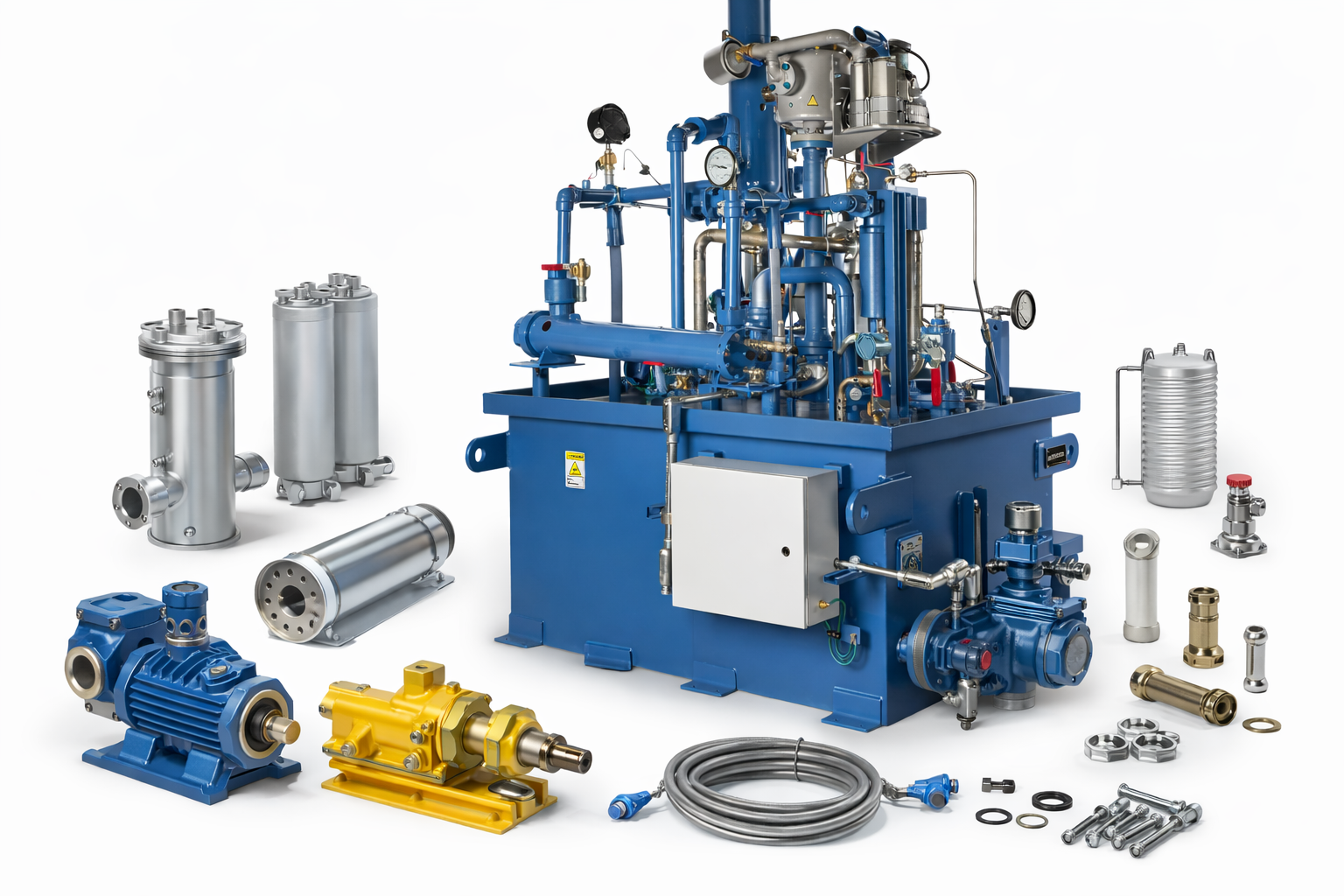

Lube Oil System Components

Complete lubrication system components ensuring smooth turbine operation.

Components/Features:

- ✔Lube oil pumps (Main/Aux Oil Pump, EOPs)

- ✔Filters and strainers

- ✔Lube Oil Assembly (PRV, Pressure Switch, Drain Valves)

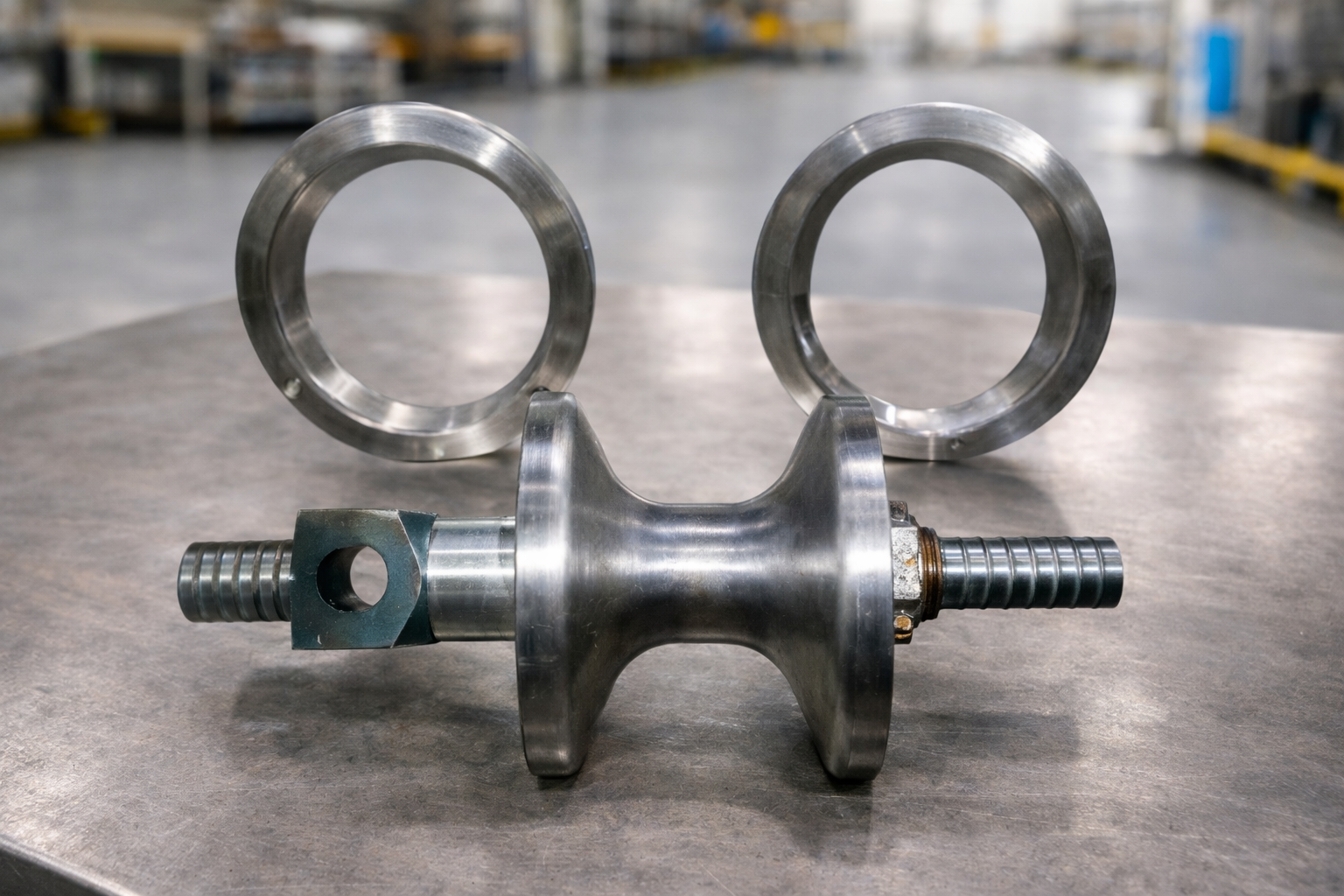

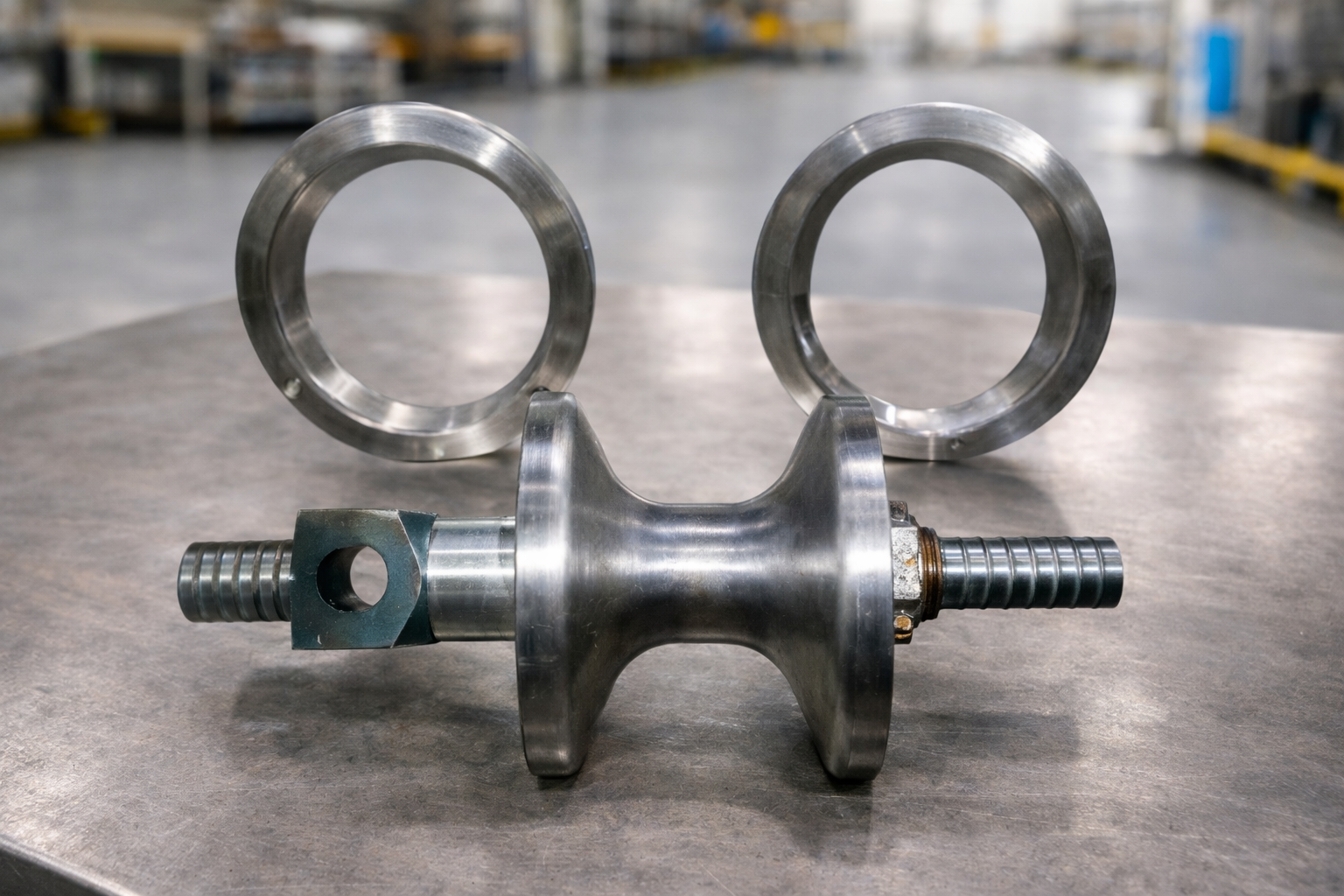

Couplings

High-strength couplings for reliable power transmission.

Components/Features:

- ✔Gear couplings

- ✔Disc-type couplings

Surface & Heat Treatment of Components

Advanced surface treatments and heat processing for superior component performance and durability

Hard Chrome Plating

Corrosion resistant coating

Nitriding

up to 600 BHN hardness

Enhanced surface hardness

Precision Grinding

High precision finishing

Heat Treatment

Optimal material properties

Steam Turbine Services

Power Your Industry with NS Terbo

Complete steam turbine solutions from manufacturing to maintenance. Partner with us for reliable, efficient power generation.

📞 Contact Us Today