Restore. Optimize. Perform.

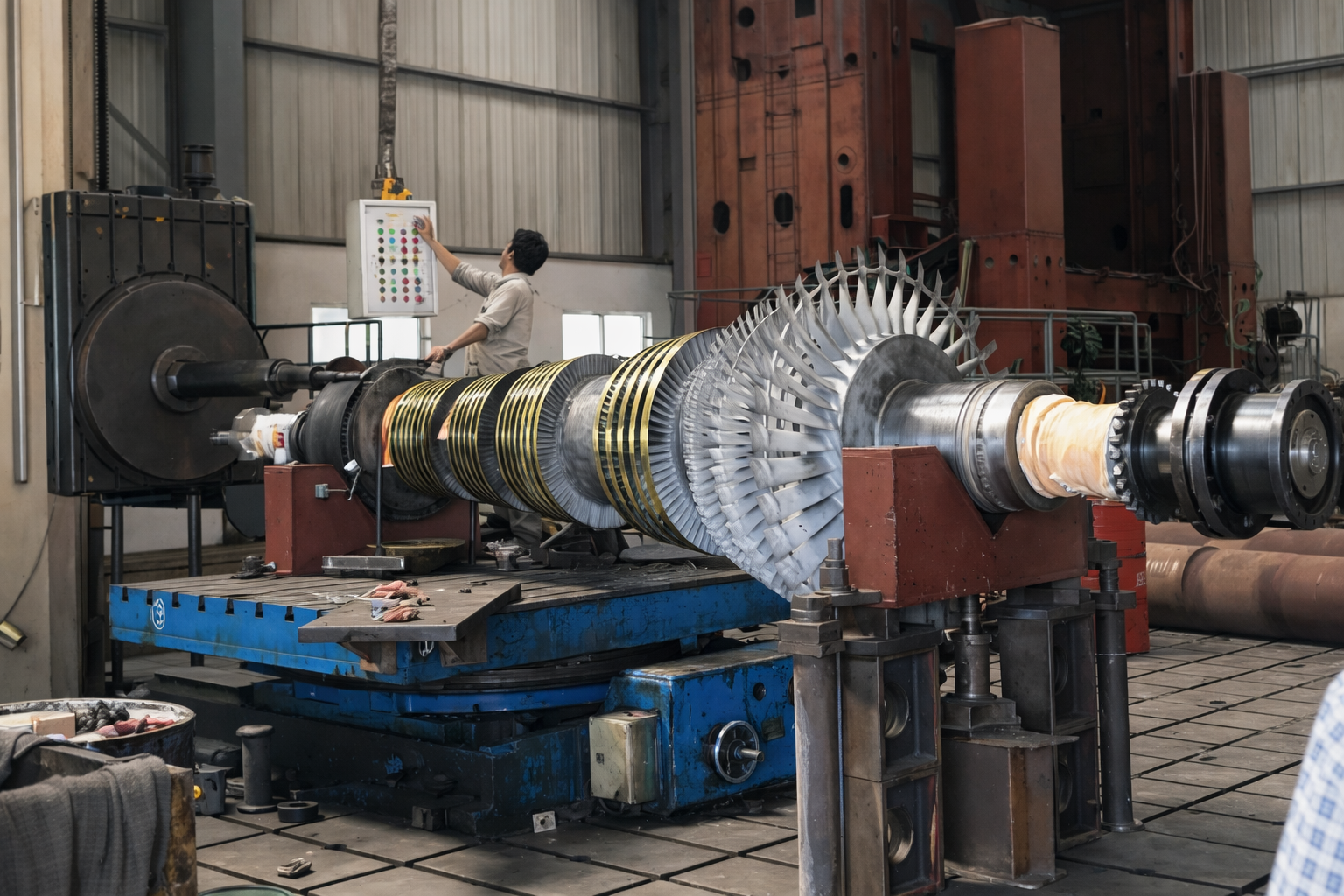

Advanced Turbine Refurbishment Solutions

Industry-leading steam turbine refurbishment and overhaul services designed to restore, upgrade, and extend the life of steam turbines of any make, any age.

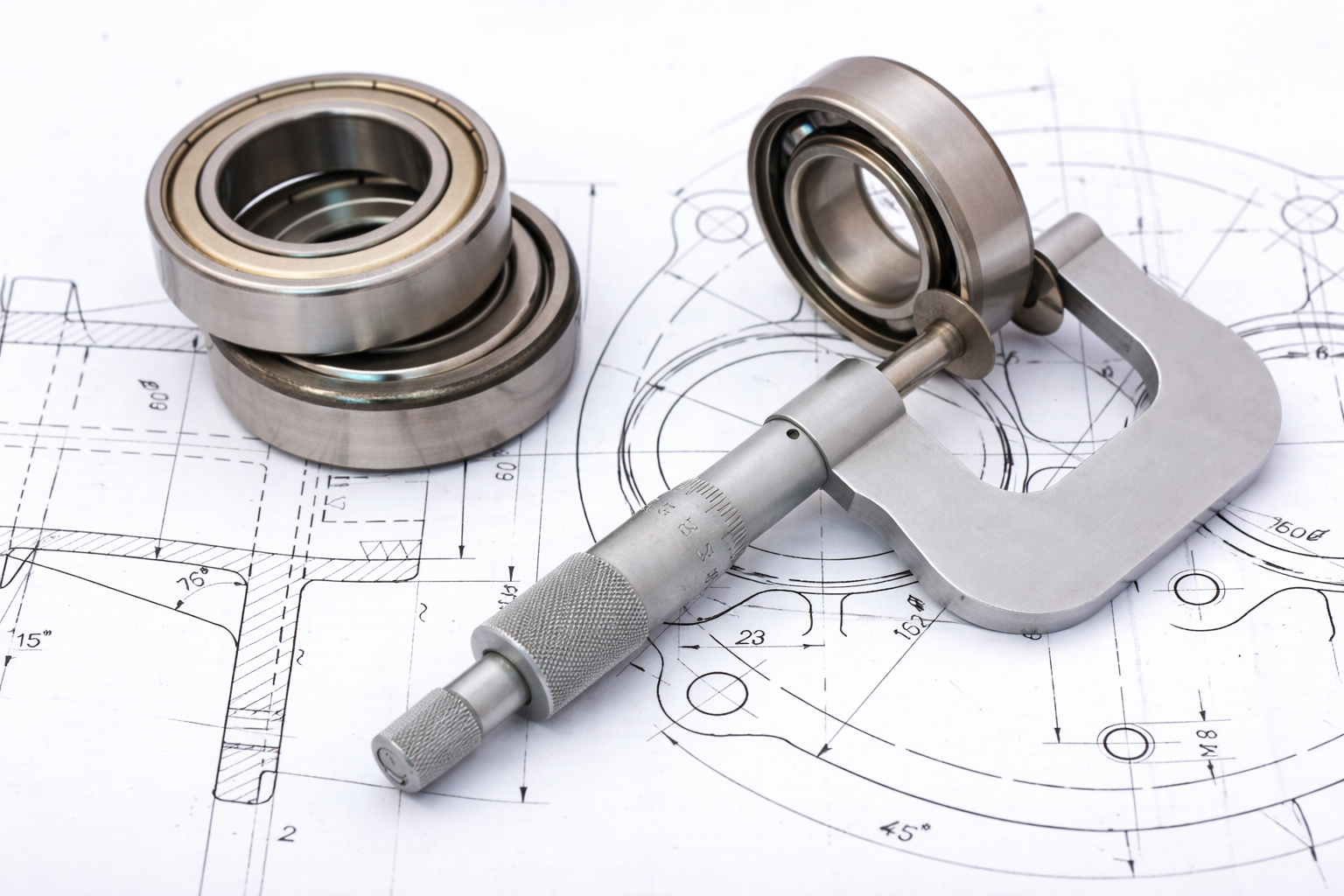

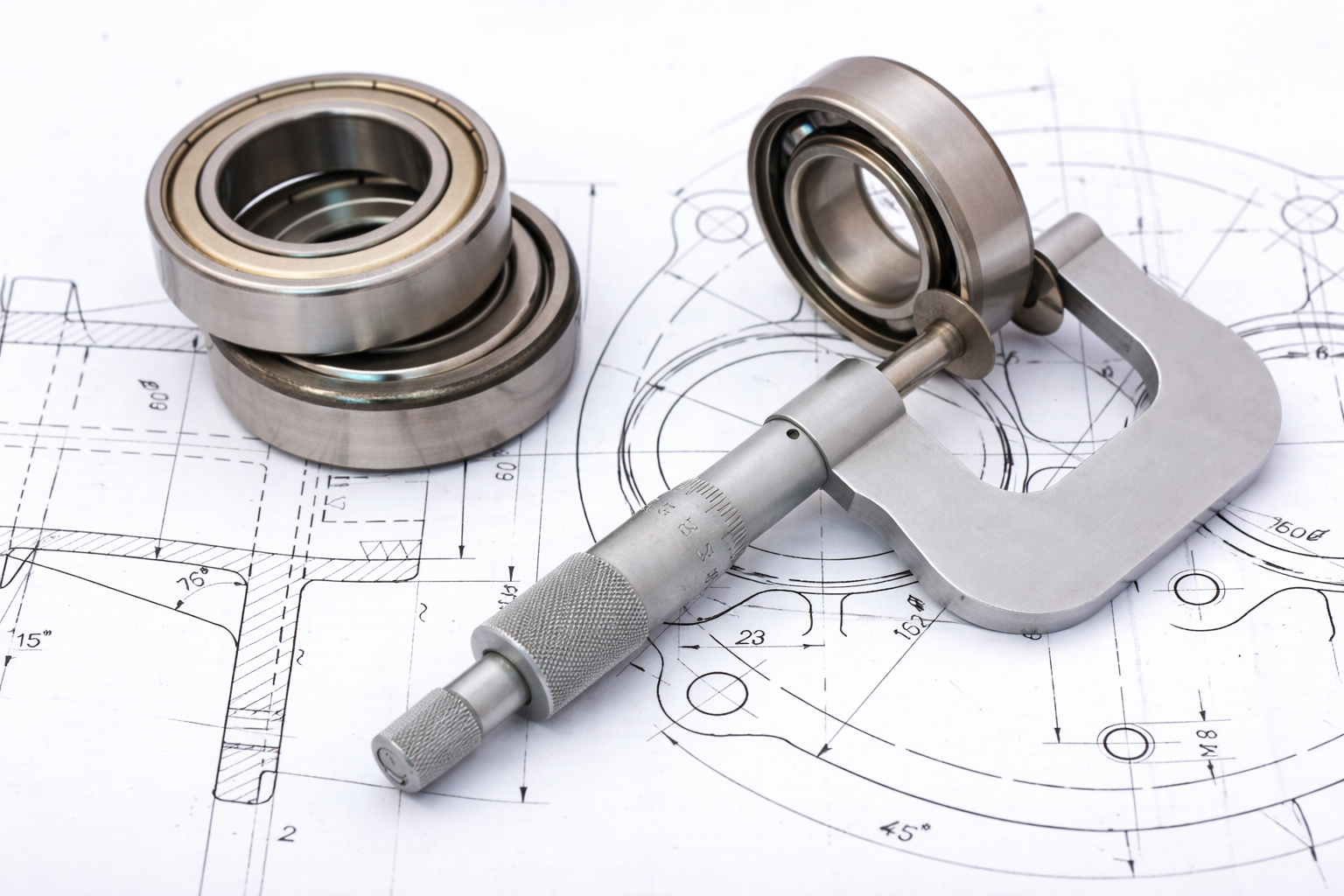

Precision Engineering Meets Modern Technology

Our refurbishment services combine precision engineering, modern diagnostic technology, and experienced craftsmanship to bring aging turbines back to peak performance, reduce downtime, and significantly improve operational efficiency.

Whether you're dealing with diminished efficiency, increased vibration, or wear-related failures, our expert team delivers customised refurbishment solutions that maximise output, reliability, and service life of your turbine assets.

Why Refurbish Your Steam Turbine?

Steam turbines naturally degrade over time — wear, erosion, and outdated internal components can lead to reduced performance and increased operating costs.

Efficiency Restoration & Enhancement

Up to 15% improvement in efficiency, resulting in lower fuel costs and better power generation.

Extended Turbine Life

Life extension of your turbine by 100,000+ operating hours with enhanced reliability.

Longer Intervals Between Overhauls

Improved maintenance cycles with extended operational spans.

Higher Return on Investment

Fast ROI through reduced downtime and increased output.

Our Refurbishment Capabilities & Services

Condition Assessment & Performance Health Checks

Reverse Engineering & Re-Engineering

Component Overhaul & Precision Repair

Advanced Balancing & Alignment

Overhaul, Installation & Commissioning Support

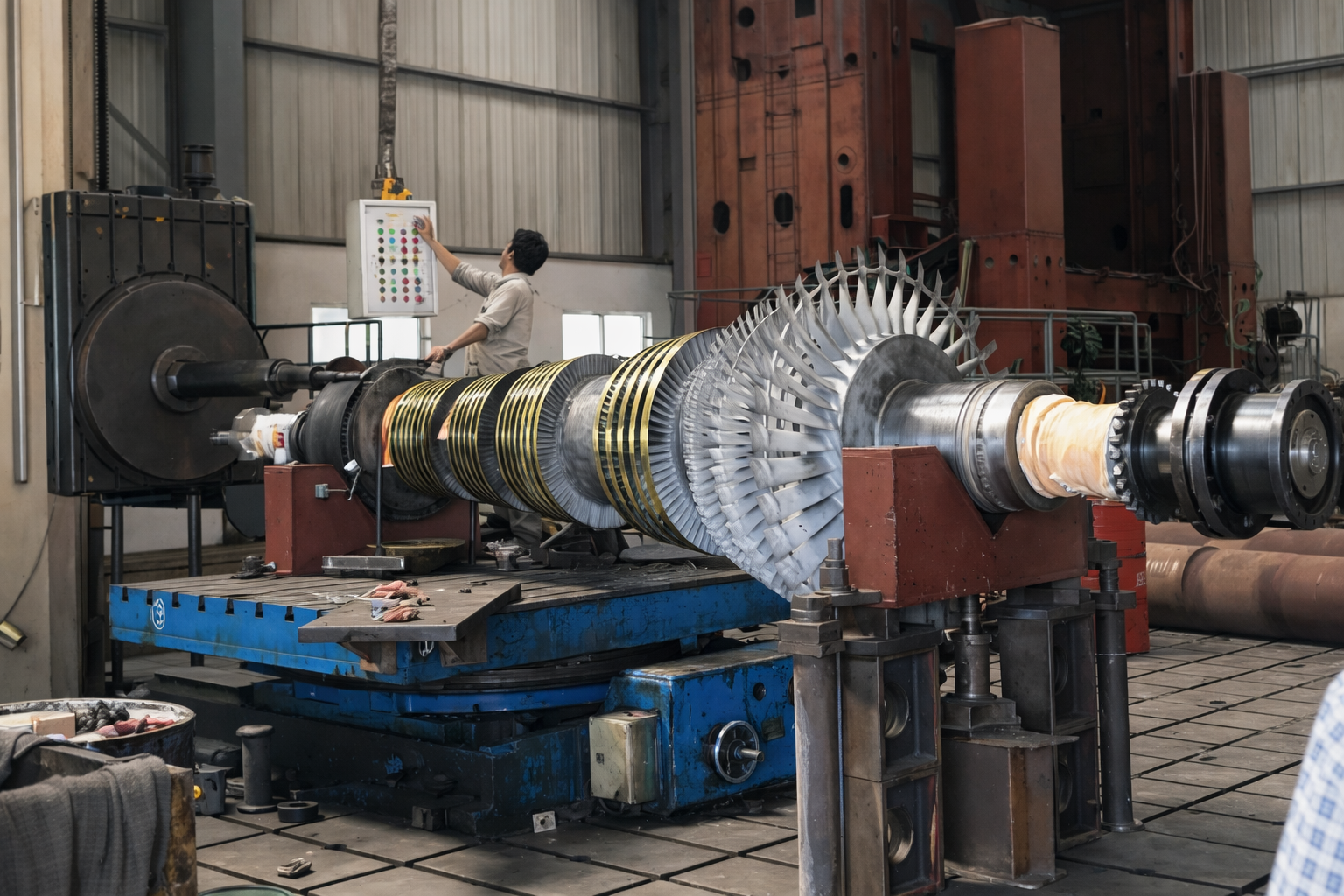

Condition Assessment & Performance Health Checks

We begin with a detailed evaluation of your steam turbine's condition using state-of-the-art diagnostic tools. This includes vibration analysis, rotor inspection, and steam path evaluations to identify inefficiencies and wear patterns early.

Key Benefits

- ✓Early detection of potential failures

- ✓Data-driven planning of refurbishment scope

- ✓Accurate life extension assessment

Reverse Engineering & Re-Engineering

Our in-house engineering team utilises advanced 3D scanning and modelling to replicate worn parts and redesign steam path components for improved flow and efficiency. This becomes critical when original drawings are unavailable or obsolete.

Key Benefits

- ✓3D scanning for precision measurements

- ✓Blade redesign for enhanced steam flow

- ✓Reverse engineered spare parts

Component Overhaul & Precision Repair

We refurbish all major components of your turbine including blades, housings, rotors, and seals. Repairs are performed to OEM tolerances to ensure restored performance.

Services Include

- ✓Blade replacement and re-profiling

- ✓Rotor straightening & dynamic balancing

- ✓Seal system overhaul

Advanced Balancing & Alignment

Dynamic balancing and precision alignment are critical to smooth turbine operation. We perform balancing to stringent accuracy standards and align turbine assemblies for minimal vibration and maximum life.

Why It Matters

- ✓Reduces mechanical stress

- ✓Improves reliability

- ✓Minimises unplanned shutdowns

Overhaul, Installation & Commissioning Support

Once refurbishment is complete, we assist with installation and commissioning, ensuring your turbine is returned to service safely and efficiently. Our technicians can also support on-site teams to ensure a seamless transition.

Why It Matters

- ✓Comprehensive overhaul planning

- ✓On-site technical assistance

- ✓Start-up & performance verification

Features That Set NS Terbo Refurb Apart

Industry-leading capabilities and expertise that ensure exceptional results

Multi-Brand Capability

We service turbines of all brands and vintages — no matter the make or age.

In-House Technology & Expertise

Advanced tooling and decades of engineering experience ensure precise refurbishment.

Full Lifecycle Support

From initial inspection to final commissioning and future upgrades, we guide you at every step.

Health Monitoring & LTSA Support

Long-Term Service Agreements (LTSA) and health monitoring plans to proactively maintain turbine performance.

Why Customers Choose NS Terbo Refurbishment

Maximize turbine uptime, reduce lifecycle costs, and ensure consistent operational performance