Downtime Minimized Power Maximized

Complete Turbine & Power Plant Lifecycle Support

We offer end-to-end steam turbine overhauling and field services for all makes and models, covering governing systems, turbo generators, high-speed centrifugal compressors, pumps, gearboxes, and critical auxiliaries such as BFPs, CEPs, and condensers used in power and process industries.

Our experienced steam turbine service engineers deliver reliable on-site maintenance, shutdown overhauls, and performance restoration with proven expertise across multiple industries. Equipped with advanced tools, measuring instruments, and testing equipment.

Our Comprehensive Services

On-Site Services

Turbine Overhauling

Troubleshooting Services

Erection & Commissioning

Repair & Refurbishment

Spares Manufacturing

Boiler Refurbishment

Manpower Services

ID / FD Fan Overhauling

BFP Overhauling & Maintenance

On-Site Services

Our on-site service team provides rapid, reliable support at customer locations for inspection, diagnosis, repair, and performance restoration.

Key Features:

- ✔On-site inspection & assessment

- ✔Emergency breakdown support

- ✔Performance evaluation

- ✔Alignment, balancing & testing

- ✔Short shutdown execution

Turbine Overhauling

Complete turbine overhauling for steam turbines of various capacities and makes. We follow structured procedures to restore mechanical integrity and performance.

Key Features:

- ✔Complete dismantling & inspection

- ✔Rotor, casing & bearing checks

- ✔Seal, blade & diaphragm inspection

- ✔Assembly, alignment & testing

- ✔Performance validation after overhaul

Troubleshooting Services

Root-cause analysis of turbine and rotating equipment problems to prevent repeat failures and improve plant reliability.

Key Features:

- ✔High vibration diagnosis

- ✔Abnormal noise investigation

- ✔Bearing failure analysis

- ✔Temperature rise solutions

- ✔Efficiency drop rectification

- ✔Repeated shutdowns prevention

Erection & Commissioning

End-to-end erection and commissioning services, ensuring proper installation, alignment, and safe startup of turbines and auxiliaries.

Key Features:

- ✔Mechanical erection supervision

- ✔Alignment & coupling checks

- ✔Lube oil system flushing

- ✔Trial runs & performance testing

- ✔Safe handover to operations team

Repair & Refurbishment

Extend equipment life and improve efficiency without heavy capital investment through our comprehensive repair services.

Key Features:

- ✔Component repair & re-engineering

- ✔Rotor, casing & blade refurbishment

- ✔Efficiency improvement upgrades

- ✔Reverse engineering of obsolete parts

- ✔Performance enhancement solutions

Spares Manufacturing

We manufacture high-quality turbine and boiler spares using CNC machining and quality control processes.

Key Features:

- ✔Turbine blades & nozzles

- ✔Shafts & Complete Rotors

- ✔Bearings & Seals

- ✔Couplings & Diaphragms

- ✔Custom engineered components

Boiler Refurbishment

Boiler refurbishment solutions to enhance operational safety, thermal efficiency, and reliability.

Key Features:

- ✔Boiler inspection & assessment

- ✔Tube replacement & repairs

- ✔Grate bar refurbishment

- ✔Pressure part repair

- ✔Performance improvement modifications

Manpower Services

Trained and experienced manpower for short-term and long-term plant operation and maintenance requirements.

Key Features:

- ✔Turbine engineers

- ✔Mechanical supervisors

- ✔Erection & maintenance technicians

- ✔Shutdown support teams

- ✔Skilled technical workforce on demand

ID / FD Fan Overhauling

ID and FD fan overhauling services ensure smooth operation, balanced performance, and reduced power consumption.

Key Features:

- ✔Impeller inspection & balancing

- ✔Bearing & shaft checks

- ✔Alignment & vibration correction

- ✔Performance restoration

- ✔Extended fan life

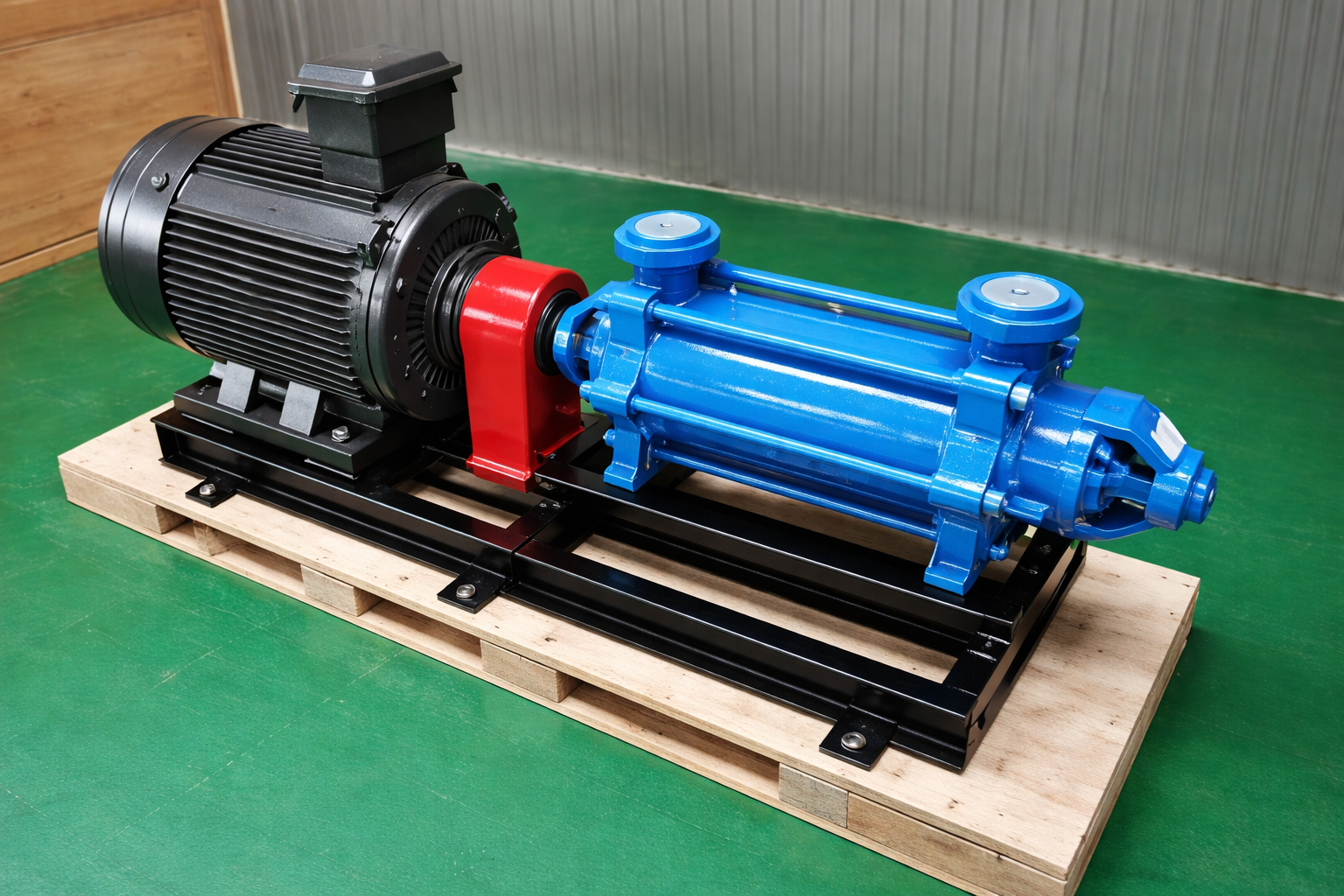

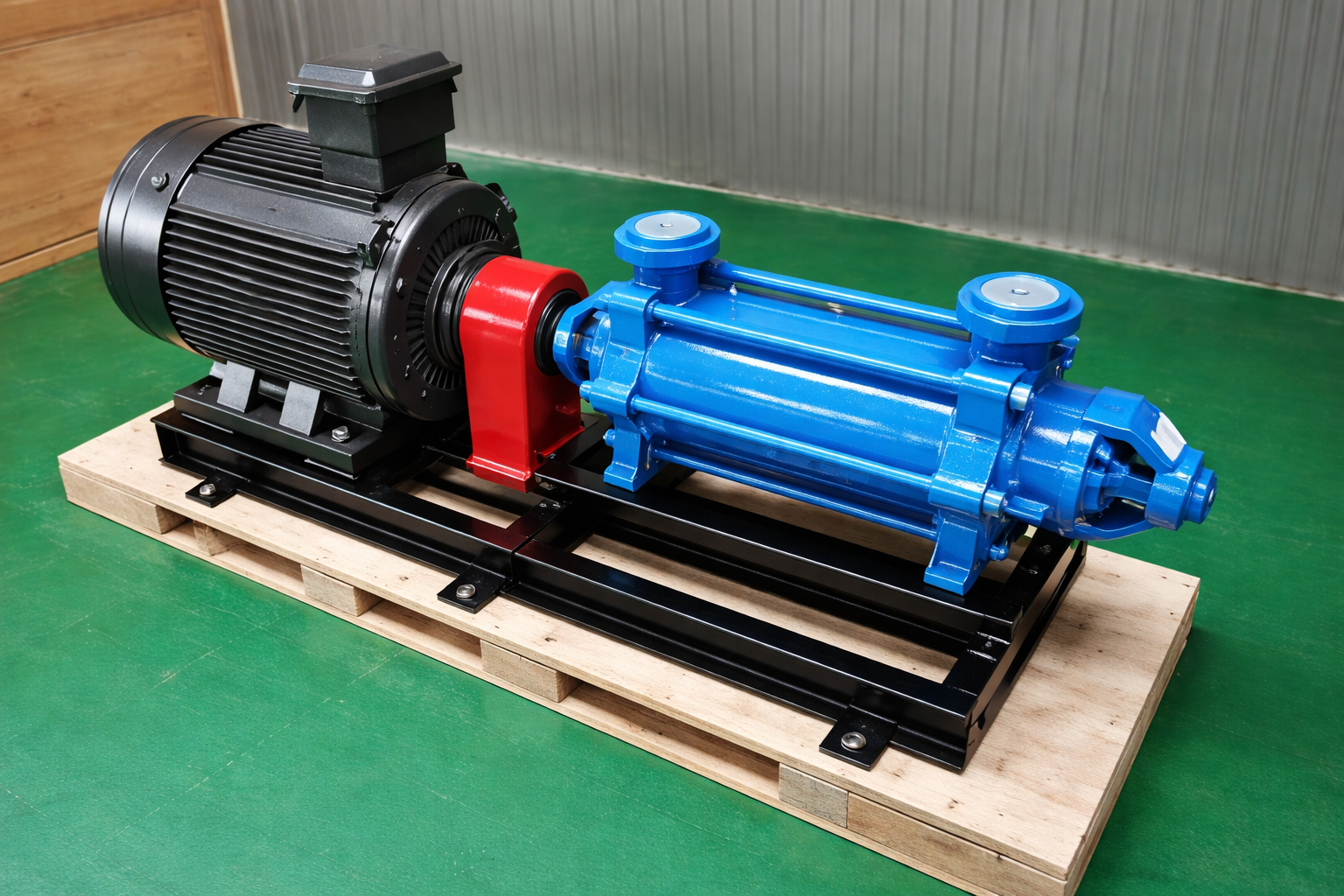

BFP Overhauling & Maintenance

Comprehensive Boiler Feed Pump (BFP) overhauling and maintenance services to ensure stable boiler operation.

Key Features:

- ✔Complete pump dismantling & inspection

- ✔Bearing & seal replacement

- ✔Rotor dynamic balancing

- ✔Re-assembly & testing

- ✔Preventive maintenance support

Why Choose N.S. Terbo?

Multi-brand Expertise

Comprehensive support for all turbine makes and models

Experienced & Certified Engineers

Field engineers with proven expertise

Fast Response & Reliable Execution

Rapid deployment for emergency situations

Cost-Effective Solutions

Optimized services without compromising quality

Focus on Safety & Performance

Prioritizing safe operations and enhanced reliability

Reduced Downtime

Simultaneous execution at multiple locations